Core Advantages

Why choose RAYTRON? We deliver exceptional value through advanced technology and proven expertise.

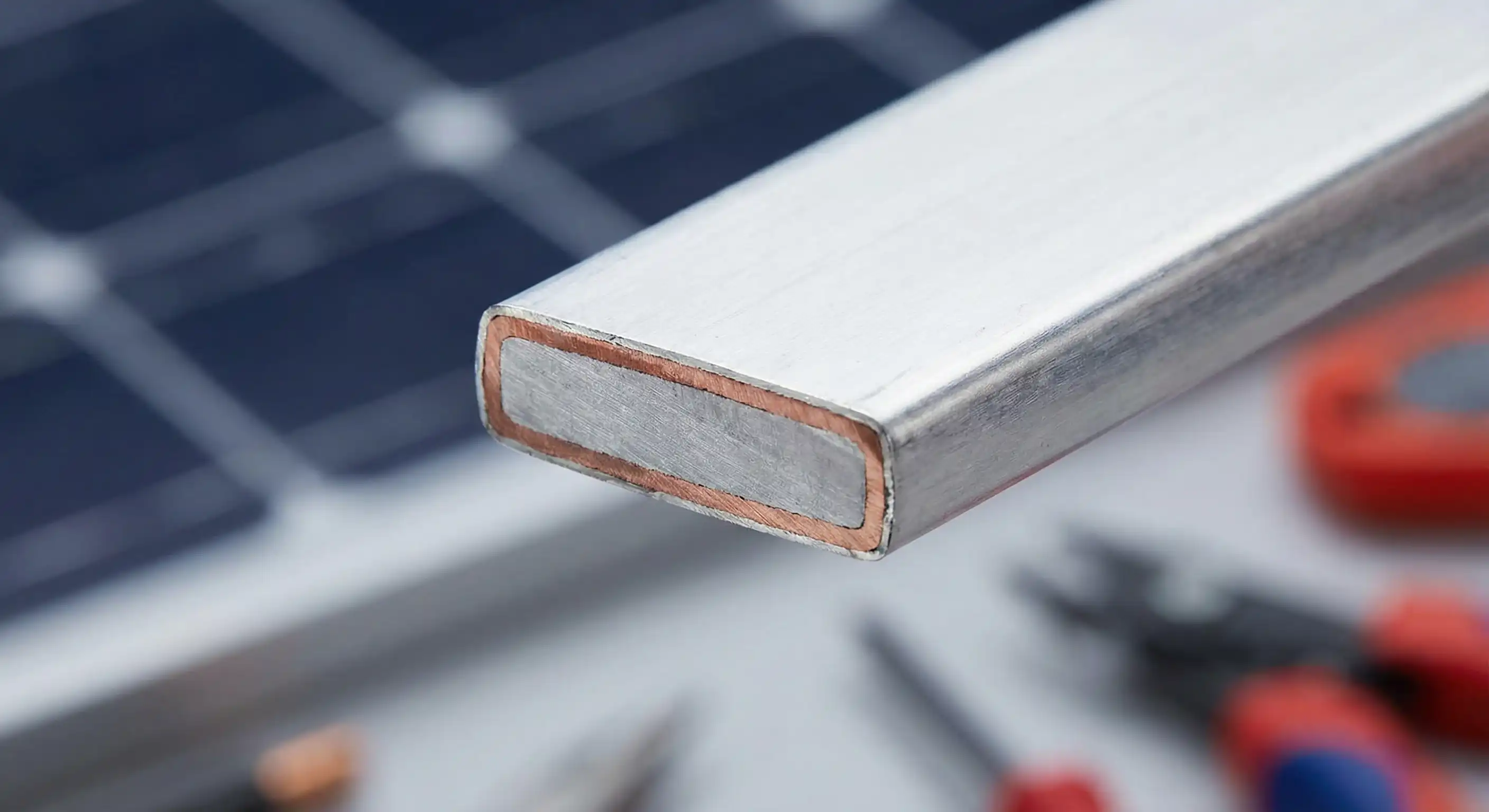

Material Engineering Excellence

Advanced metallurgical bonding technology ensures superior interface strength and consistent performance across all applications.

Learn MoreRapid Prototyping

Fast sample development and customization capabilities accelerate your time-to-market with precision-engineered solutions.

Get StartedQuality Traceability

Complete batch tracking system ensures every product meets strict quality standards and provides full traceability.

View QualityTechnical Capabilities

Industry-leading specifications backed by advanced manufacturing technology

Production Capacity

24,000 tons/year with flexible scheduling to meet your demand

Precision Tolerance

±2μm level dimensional control for critical applications

Fast Delivery

Sample lead time: 3-7 days, mass production: 7-14 days

Industry Solutions

Tailored bimetallic solutions for diverse applications

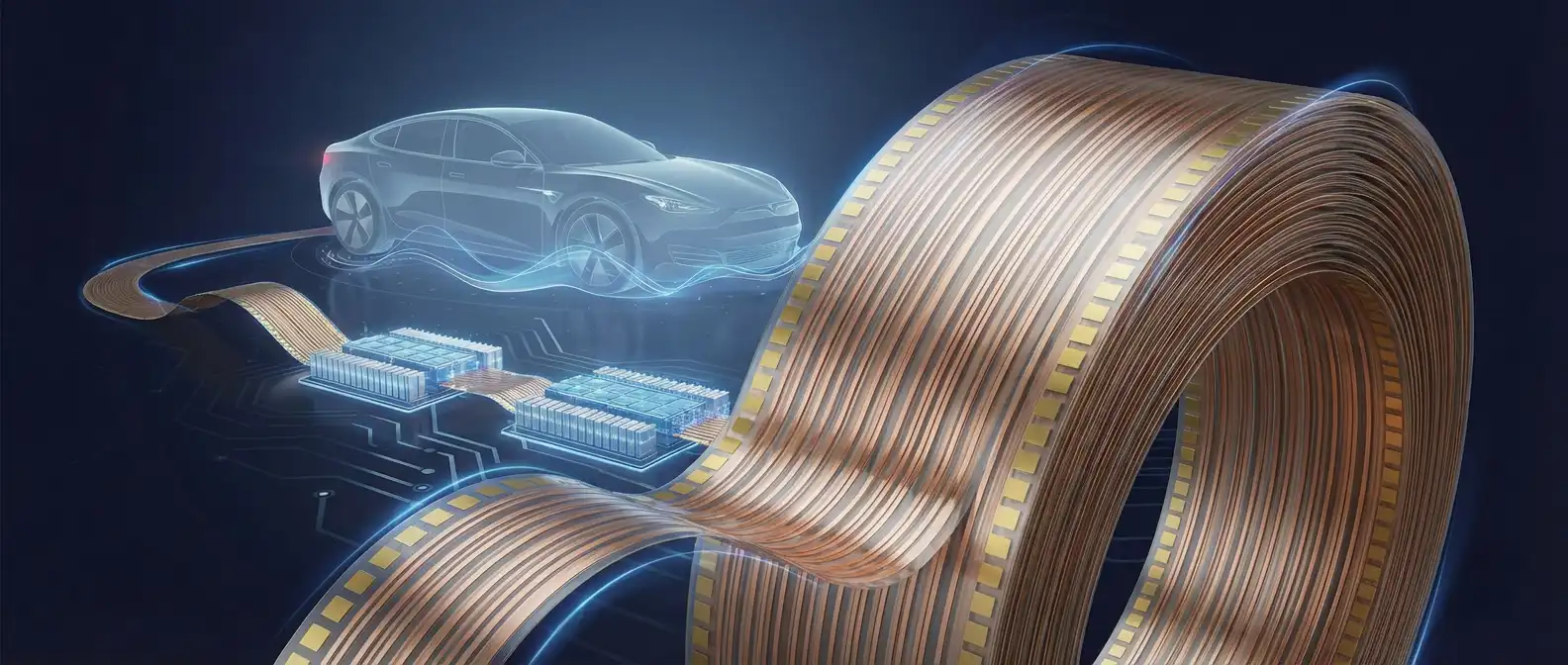

Automotive EV

Advanced materials for electric vehicle motors, charging systems, and power electronics

Learn More →Photovoltaic Solar

Specialized ribbons and conductors for solar panel manufacturing and renewable energy

Learn More →Battery Energy Storage

Lightweight, high-conductivity materials for battery tabs, busbars, and connectors

Learn More →Cable & Conductor

High-performance CCA and CCS for cable manufacturing, telecommunications, and power transmission

Learn More →Electronics & Semiconductors

Precision materials for connectors, lead frames, and electronic components

Learn More →Aerospace & Defense

High-performance materials for aerospace, defense, and specialized applications

Learn More →Customer Cases

Real-world success stories from our global partners

EV Battery Lightweight Solution

PV Ribbon Cost Reduction

eVTOL Motor Lightweight Solution

Quality Certifications

Our commitment to excellence through rigorous quality standards and industry certifications