Manufacturing Process

This product is manufactured using Clad & Weld process with metallurgical bonding. It is NOT electroplated.

Metallurgical bonding creates a permanent atomic-level connection, ensuring superior reliability compared to electroplating. This enables excellent weldability, resistance to peeling during bending, and stable performance under thermal cycling conditions.

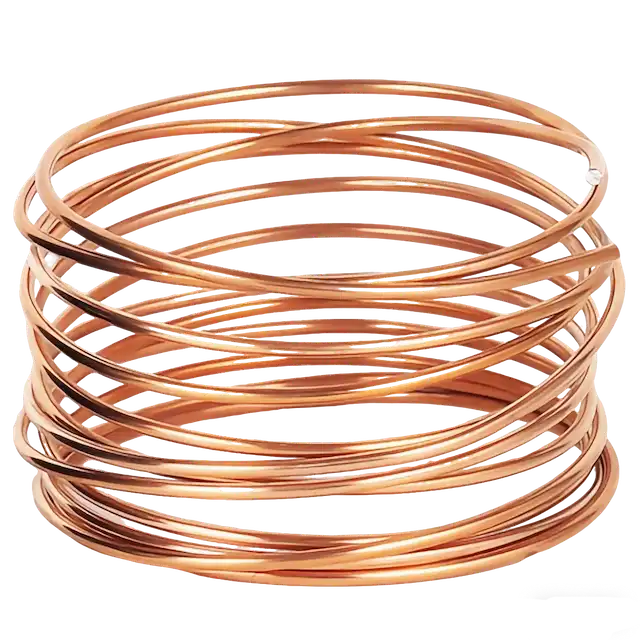

Photovoltaic Ribbon

High-precision welding ribbon designed for photovoltaic modules, providing excellent conductivity and welding performance, effectively reducing micro-crack risk and improving module conversion efficiency.

Material

Tinned Copper/Silver-Copper Alloy

Conductivity

98% IACS

Tensile Strength

220 MPa

Diameter

Width: 0.6mm-2.5mm, Thickness: 0.1mm-0.3mm

Applications

Detailed Specs

| Specification | Value |

|---|---|

| Material | Tinned Copper, Silver-Copper Alloy |

| Standards | IEC 62804, JIS C3317 |

| Temper | Soft |

| Coating Thickness | 2-10μm |

Frequently Asked Questions

Related Products

Enameled Round Wire

Copper/Aluminum + Insulation Enamel

Enameled Flat Wire

Copper/Aluminum + Insulation Enamel

Enameled Strip

Copper/Aluminum + Insulation Enamel

Enameled Ribbon Wire

Copper/Aluminum + Insulation Enamel

Custom Specialty Metals

Customized according to customer requirements

Title

Description

Image Caption